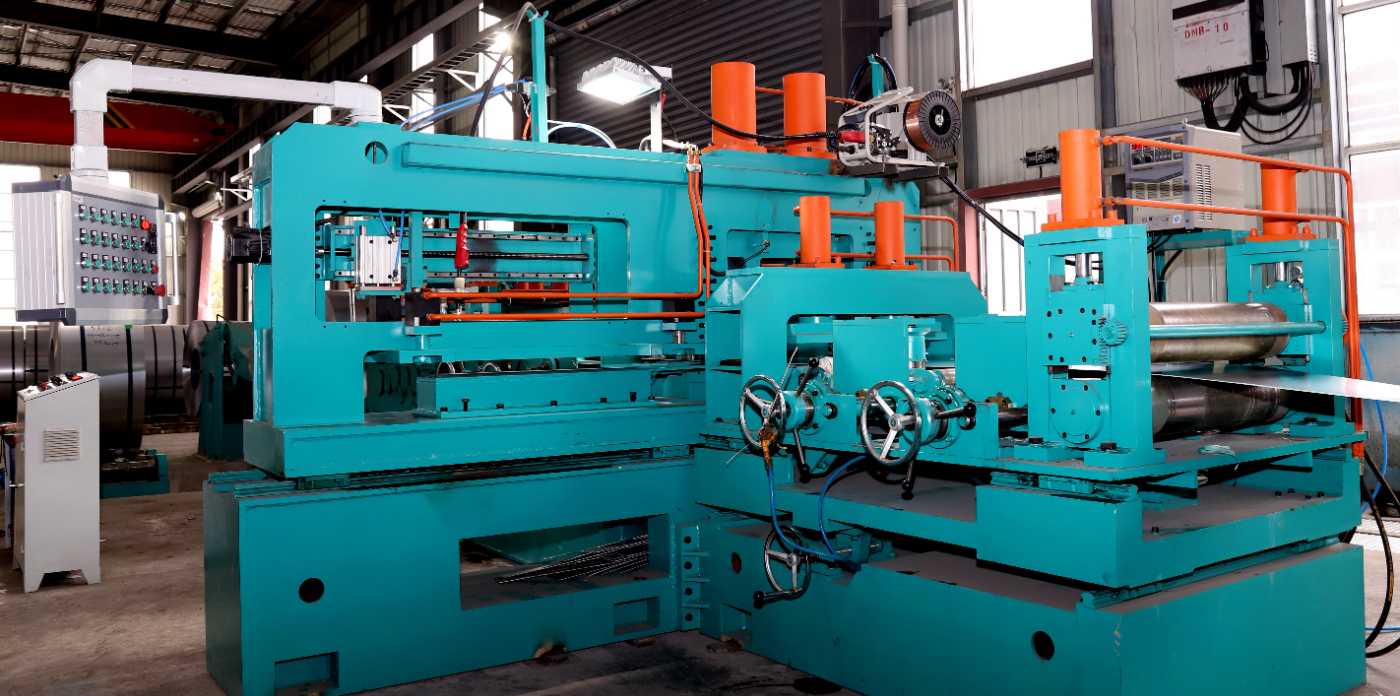

Shear and Welder

The Shear and Welder is an essential auxiliary machine for shearing and butt welding irregular parts at the head and tail of steel strips. This process prepares the material for continuous production in welded pipe manufacturing, ensuring seamless connections and efficient production flow.

Precision Shearing & Welding:

The machine shears and butt welds steel strip ends, ensuring clean, strong connections for continuous production.

High-Speed Operation:

Designed for fast shearing and welding, it ensures uninterrupted material flow and optimizes production speed.

Fully Automated:

Reduces manual intervention, minimizes human error, and enhances safety and efficiency.

Consistent Weld Quality:

Delivers high-quality welds for strong, reliable connections without defects.

The Shear and Welder shears the steel strip ends, then butt welds them automatically, creating smooth, strong joints for continuous feeding. This process ensures consistent material flow and reduces production stoppages.

Welded Pipe Production:

Used for continuous welding in ERW pipe lines, ensuring smooth, uninterrupted production.

Metal Processing:

Ideal for shearing and welding steel strips in various metalworking applications.

Increased Efficiency:

Faster shearing and welding reduce downtime, boosting production speed.

Improved Weld Quality:

Consistent, strong welds improve final product strength and reduce defects.

Lower Labor Costs:

Fully automated, reducing the need for manual intervention and minimizing errors.

Ready to optimize your production? Contact us now for a custom quote or more information on how the Shear and Welder can boost your production line’s efficiency.

25+ Years of Experience:

Trusted by leading manufacturers for high-quality, reliable equipment.

Customized Solutions:

We offer tailored equipment to meet your specific production needs.

Reliable After-Sales Service:

Comprehensive support, including installation, maintenance, and spare parts.