Products

Shijiazhuang Great Wall equipment – Your Trusted Tube Mill Solutions Provider

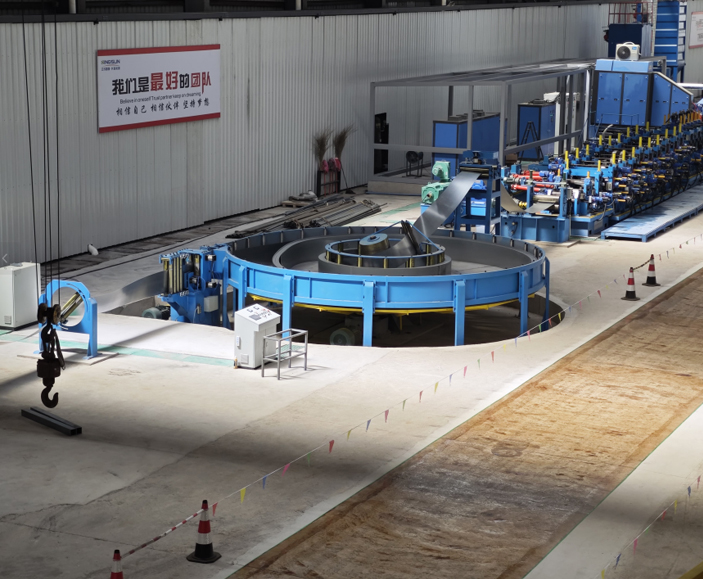

As a reliable supplier of welded pipe equipment, Shijiazhuang Great Wall Welded Pipe Equipment Co., Ltd. offers advanced Tube Mill systems that redefine efficiency and precision in pipe production. Our integrated solutions seamlessly coordinate every stage of the process—from coil uncoiling to final pipe forming—delivering reliable, high-quality results for diverse industrial needs.Whether for large-scale infrastructure or niche applications, our solutions deliver consistent quality and productivity. Contact us today to transform your pipe manufacturing process.

Production Line Performance & Features

Great Wall slitting line designed for processing coils of varied specifications, this production line completes the entire workflow from uncoiling and initial flattening to head cutting, slitting, and finally rewinding into coils with the required fixed width. Suitable for processing materials from thin sheets to thick plates, typically within a thickness range of 0.2 mm to 30 mm (depending on the machine model). As an integrated automatic coil processing equipment that combines mechanics, electricity, hydraulics, and pneumatics, it stands out for its user-friendly operation, rational layout, high automation level, and efficient processing capabilities.

Capable of handling multiple metal types, including carbon steel, cold-rolled sheets, galvanized sheets, silicon steel sheets stainless steel, aluminum alloys, copper, and other metals. Thanks to its advanced processing technology, the production line ensures consistent precision in coil width and flatness—effectively reducing material waste caused by dimensional errors, and meeting the strict quality requirements of high-end metal processing projects. Moreover, it is equipped with an intuitive human-machine interface (HMI) that allows operators to set parameters, monitor the production process, and troubleshoot simply, minimizing the learning curve for new users.

Versatile Application Scope

Welded Pipe Industry: It processes metal strips (such as carbon steel strips or stainless steel strips) into uniform narrow-width materials with precise dimensional control—these strips serve as the core raw material for welded pipe production, ensuring the subsequent pipe-forming and welding processes meet industry quality standards.

Automotive Manufacturing Industry: The machine specializes in processing high-strength steel strips, which are essential for manufacturing durable automotive components that meet strict safety and performance standards.

Solar Bracket Manufacturing Field: It precisely slits metal sheets (such as aluminum alloy sheets or galvanized steel sheets) into customized widths and sizes, supplying high-precision raw materials for assembling solar brackets—ensuring the brackets have stable structural performance to withstand outdoor environmental conditions.

Construction Sector: It processes galvanized steel and color-coated steel, producing materials that are widely used in manufacturing roofing products and structural components for construction projects.

Technical Parameters:

| Specification Model | 0.3-3.0x800-2000mm |

| Processing Materials | Cold-rolled steel, galvanized steel, stainless steel, automotive sheets, etc |

| Coil Width | 800-2000mm |

| Coil Thickness | 0.3-3.0mm |

| Coil Weight | 20T |

| Production Line Speed | 100-180m/min |

| Number of Strips | 30 strips |

| Floor Area | 24mX9m |

| Installed Capacity | 300Kw |

| As the product is constantly being improved, this technical data is for reference only. For details, please consult us | |

Introduction to Auxiliary Equipment on the Production Line

We also provide a series of auxiliary equipment, including loading trolley, uncoiler, straight head, pinching and leveling machine, shearing and welding machine, spiral accumulator, solid-state high-frequency welding machine, flying saw, and automatic stacking and strapping machine. These equipment cover the entire process of steel strip storage and transportation, uncoiling and leveling, welding and forming, steel pipe cutting, and finished product stacking, helping the production line operate efficiently and stably.

Introduction to Spare Parts

We provide spare parts such as pipe mill rollers, flying saw blades, slitting knives, and bar magnets to meet diverse customer needs. From the initial purchase to the operation of the equipment, in case of component wear, our high-quality and highly adaptable spare parts continuously ensure the stable operation of customers' production lines.

Contact Us

Welcome to contact us, your every inquiry is highly valued, and we look forward to working with you to create a better cooperation