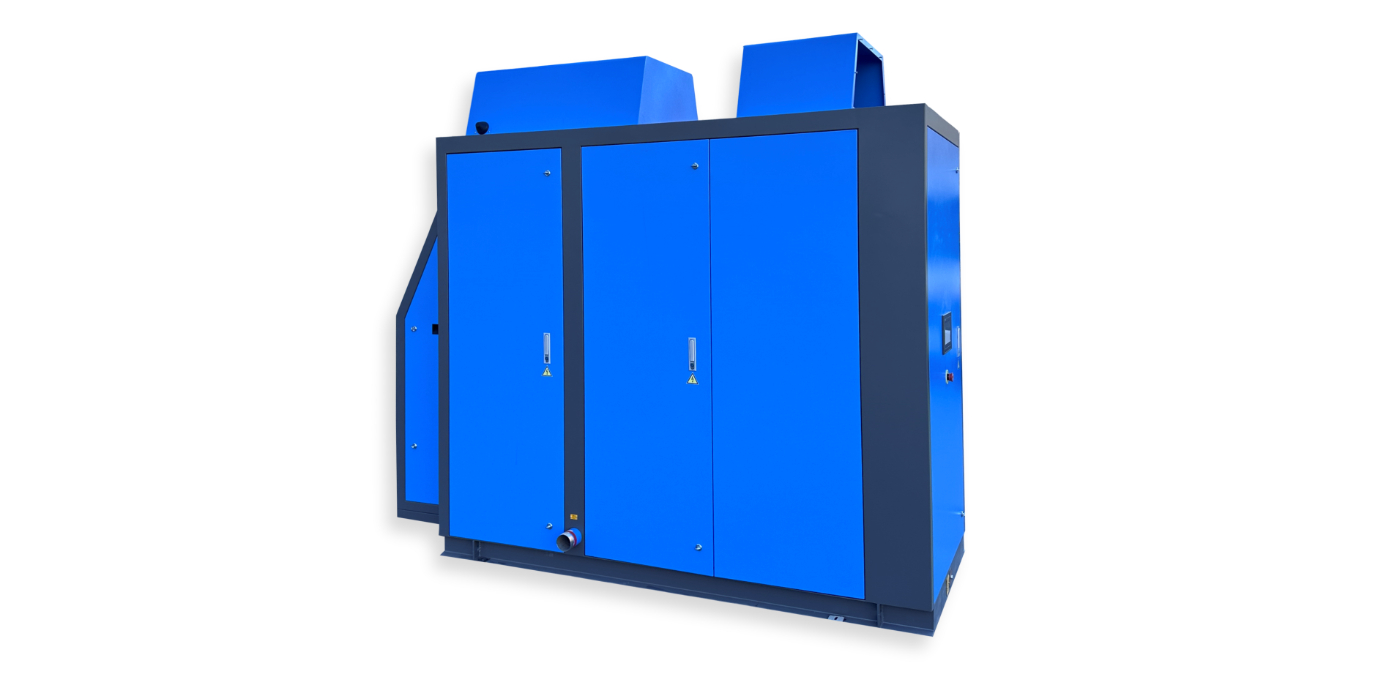

High Frequency Welder Machine

The High Frequency Welder Machine uses high-frequency current to generate heat on the surface of steel. This process rapidly heats the edges of the pipe, bringing them to the optimal welding temperature. The welding is then completed using extrusion rollers, ensuring a strong and consistent weld. Ideal for high-quality ERW welded pipe production, this machine delivers high-speed, reliable welding with minimal material waste.

High-Speed Welding:

Uses high-frequency current to quickly heat steel edges to the required temperature for fast welding, optimizing production speed.

Precise Weld Quality:

Delivers consistent, high-quality welds with strong seams, ensuring reliable and durable final products.

Efficient Heat Generation:

Efficiently generates heat on the steel surface, minimizing energy consumption and enhancing welding efficiency.

Minimal Material Waste:

The machine's precise heating process reduces material waste, making it an eco-friendly option for high-volume production.

The High Frequency Welder Machine generates high-frequency current that heats the edges of steel pipes to the required temperature in a fraction of a second. Once heated, the extrusion rollers apply pressure, completing the weld. This method ensures a clean, strong, and precise weld, suitable for high-speed production environments.

ERW Welded Pipe Production:

Perfect for welding steel pipes in ERW pipe production lines, ensuring fast and reliable connections.

Metal Manufacturing:

Used in various metalworking applications where high-speed, precision welding is required.

Increased Production Speed:

Fast welding times reduce overall production cycles, increasing output.

High Precision:

The high-frequency process ensures precise heat control, resulting in stronger and more consistent welds.

Energy Efficient:

The efficient heat generation process reduces energy consumption compared to traditional welding methods.

Installation & Setup:

Full installation and testing to ensure optimal performance right from the start.

Technical Support:

24/7 technical assistance to address any operational issues.

Spare Parts Availability:

Fast access to spare parts to minimize downtime and keep your production running smoothly.

Contact us today for more information or a quote. Reach out now to optimize your production process with advanced welding technology!