Auxiliary Equipment

Introduction to Auxiliary Equipment on the Production Line

We also provide a series of auxiliary equipment, including loading trolley, uncoiler, straight head, pinching and leveling machine, shearing and welding machine, spiral accumulator, solid-state high-frequency welding machine, flying saw, and automatic stacking and strapping machine. These equipment cover the entire process of steel strip storage and transportation, uncoiling and leveling, welding and forming, steel pipe cutting, and finished product stacking, helping the production line operate efficiently and stably.

See All

Used to support the steel coils and rotate the steel coils. Cooperate with the straight head device to decoil the steel coils and smoothly enter the accumulator.

The straight head cooperates with the uncoiling machine to decoil the steel strips, which has the function of plate tail impact protection. The pinch roller delivers the strip steel, sent the head of the strip steel is into the leveling roller to actively level the head and tail of the strip steel and passively level the strip steel throughout the process.

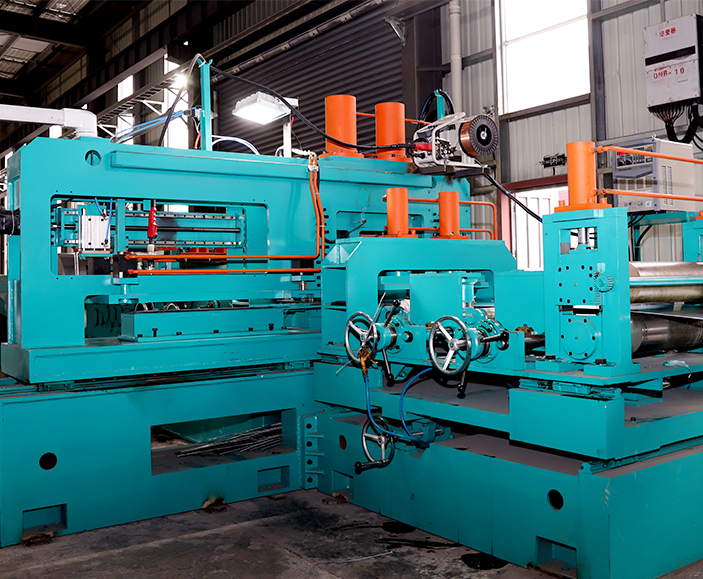

Shearing and welding machine: used for shearing and butt welding of irregular parts of the head and tail of the strip steel, to prepare for the continuous production of welded pipes.

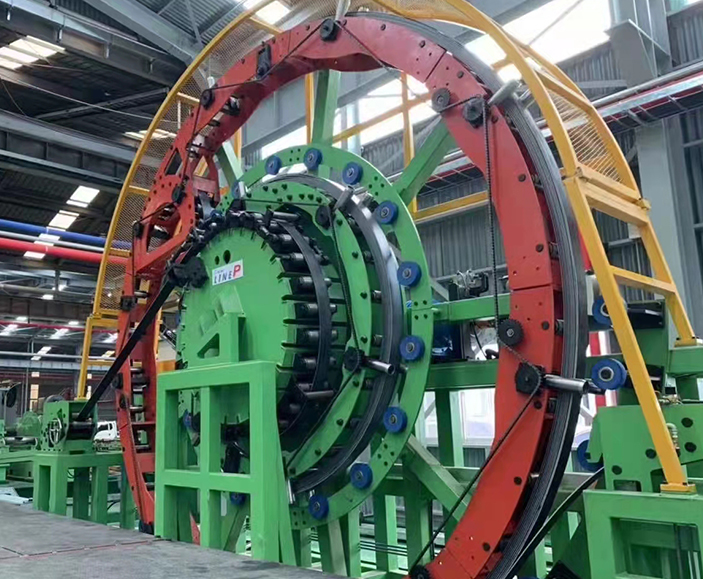

Used to store steel strips, which not only feeds the forming unit to ensure the continuous production of the forming unit, but also provides a time interval for completing the connection of the strip coils.

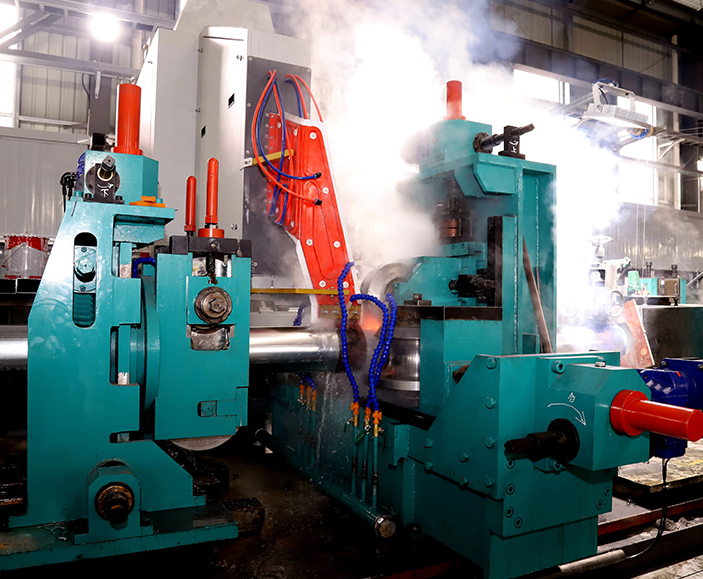

Use high-frequency current to generate heat on the surface of steel, so that the edge of the pipe is quickly heated to the welding temperature, and the welding is completed with the extrusion roller.

Application: It is an important equipment on the welded pipe production line. It automatically and precisely saws pipes of various shapes at high speed. Due to the adoption of a fast and high-precision STD control system and mechanical system, it has excellent fixed-length and synchronization performance, as well as reliable mechanical transmission. Therefore, this machine features good rapid performance and high precision.

Hot-cut saws can be customized according to different pipe diameters, thicknesses and speeds

It is divided into cold cutting saw and hot cutting saw. Cut the long steel pipe into short pipes of the required length online. The cold cutting saw can remove burrs and chamfers during the cutting process.

Automatically complete the collection and stacking of welded pipes at the end of the welded pipe production line, automatically run smoothly, reduce manual labor intensity, and improve the degree of automation of the production line.

Contact Us

Welcome to contact us, your every inquiry is highly valued, and we look forward to working with you to create a better cooperation